Sizing a Right Angle Gearbox:

Tips To Get Started

When your equipment calls for a right angle gearbox, proper sizing makes a difference. A wide range of application factors must be considered, or you will face problems down the road. This blog post will provide an overview of three important criteria to consider before sizing your gearbox: target speed, output torque and service factor.

Determine Your Target Speed and Output Torque

To begin sizing, determine the horsepower or torque that must be transmitted in the application. Next, consider how fast the output shaft will turn to meet your requirements. Also review both the axial and radial loads applied to the gearbox shafts.

As power and torque requirements increase, the gearset diameter will also increase to transmit the larger forces. As the gearset grows in diameter, the gearbox housing must grow to accommodate the larger gears. Knowing the power and speed, you can always calculate the torque. Or, by knowing the torque and speed, you can calculate the power.

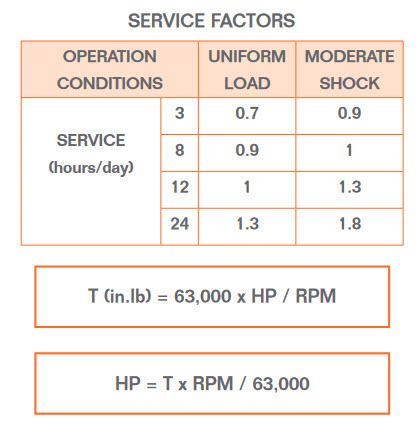

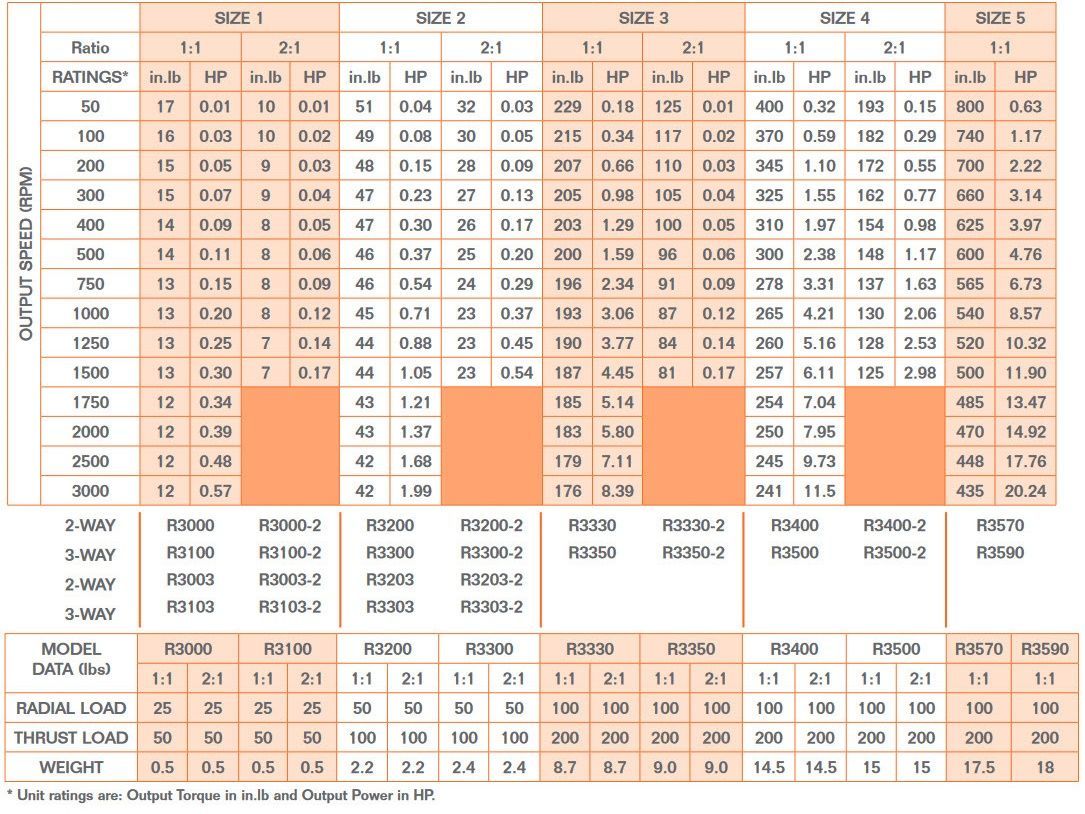

The formulae for determining torque and horsepower are shown in Table 1. The axial and radial load ratings can be found in Table 2.

Table 2

When a right angle gearbox is subjected to a higher torque or horsepower load than its rating, the overload situation will eventually shorten its lifetime. If the overload is mild in severity, the gearbox may operate normally for some period of time before the increased wear makes replacement necessary. Severe overloading can result in damaged bearings, broken gear teeth or both. When the axial or radial load ratings are exceeded, it will shorten the life of the bearing thus reducing the between-gearbox replacement. This is why some gearbox specifiers may be tempted to size the gearbox to the drive motor, resulting in an oversized gearbox.

For example, if the application requires ¾ hp, a motor manufacturer may recommend a 1-hp motor. When it’s time to select the gearbox, the customer may in turn be inclined to select the appropriate gearbox for 1 hp, which may be a unit rated for 1 ½ hp. The gearbox will be capable of transmitting much greater torque than required, but it will come with a higher price tag, size and weight. That’s why it’s important to determine your gearbox’s service factor requirements.

Understand Service Factor

Gearbox manufacturers typically publish charts that account for the working conditions the gearbox is expected to withstand such as hours of service per day and the type of load — uniform and moderate shock. Note that high-shock or impact loads can prematurely damage gear teeth and bearings. If you expect the application to impose non-uniform loads on a gearbox, be sure to consult the manufacturer to determine the appropriate service factor that will account for those loads.

With this information, you can begin sizing a gearbox according to the manufacturer’s instructions. Redex provides step-by-step sizing instructions in the ANGLgear catalog and the new white paper, More Than Just Motor Size: Use Application Information to Size Your Gearbox Correctly.

For more information about sizing Redex ANGLgear right angle gearboxes, download the white paper.